Clemson program to address manufacturing skills gap

Staff Report //September 10, 2018//

A $3 million grant from the National Science Foundation has helped Clemson University put together a Technology- Human Integrated Knowledge, Education and Research program, also known as THINKER. The program matches graduate students with technical college students on an assembly line built for research.

The goal of the program is to at create well-prepared leaders who can help close the skills gap in advanced manufacturing. By going through the program, those leaders will understand the interaction of machines, people and data, according to a news release.

Economic expansion and baby boomer retirements will likely create a need to fill 3.4 million manufacturing jobs in the nation between 2015 and 2025, but only 1.4 million are likely to be adequately filled, according to a study by Deloitte and the Manufacturing Institute, the release said.

Economic expansion and baby boomer retirements will likely create a need to fill 3.4 million manufacturing jobs in the nation between 2015 and 2025, but only 1.4 million are likely to be adequately filled, according to a study by Deloitte and the Manufacturing Institute, the release said.

Laine Mears, the BMW SmartState Chair in Automotive Manufacturing at Clemson, said the THINKER team will be creating a new national model for graduate education.

“We do that by putting students into a manufacturing environment and teaching them how people and technology work together and how new technologies can emerge to support that vision,” he said, in the release.

Graduate students who enroll in THINKER will lead teams of undergraduate and technical college students in research projects suggested by industry.

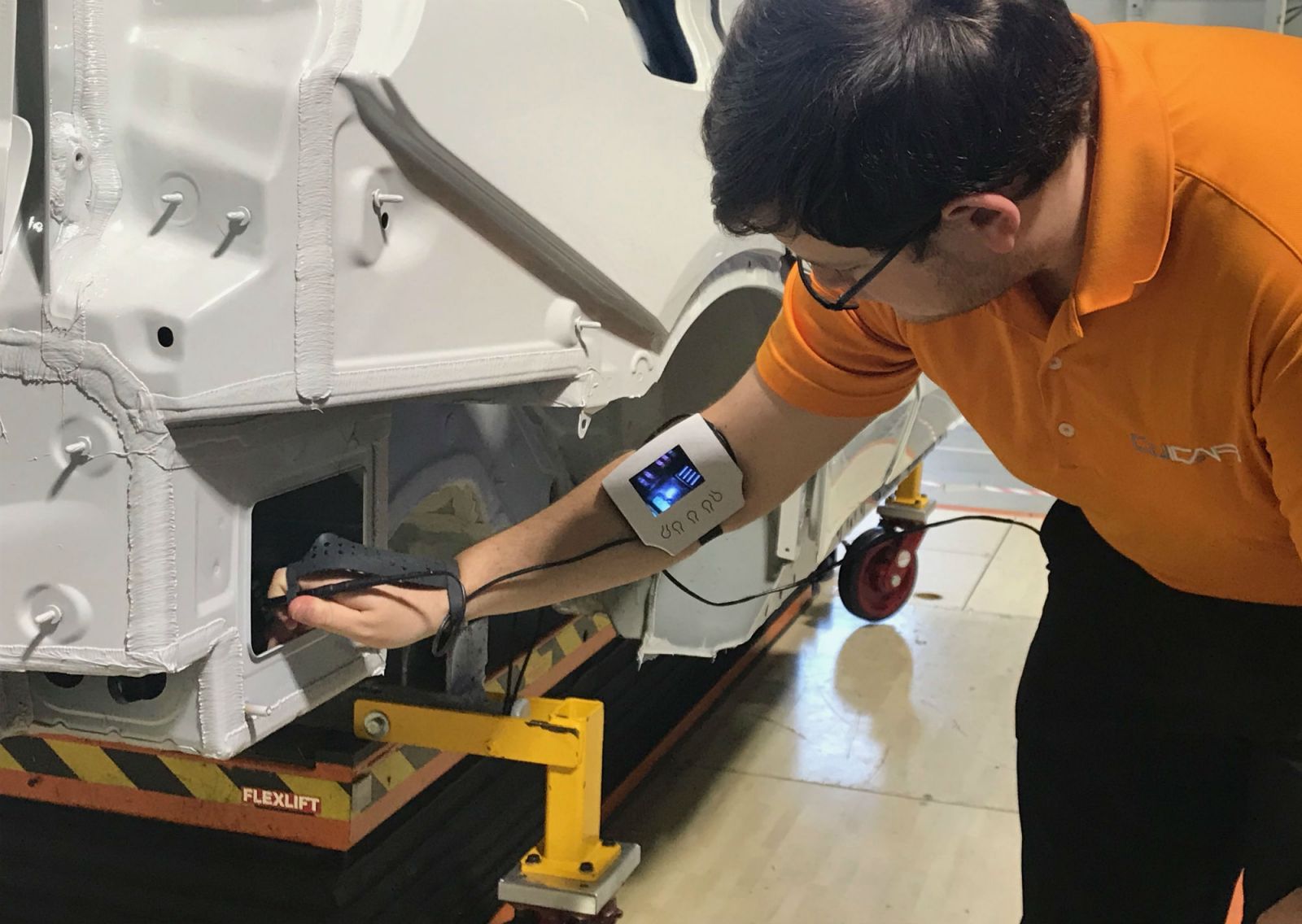

The teams will focus their research on connecting human workers and internet-connected machines that are often loaded with sensors and generating massive amounts of data. A wide range of research projects could be involved, such as developing new manufacturing processes or creating wearable devices that give workers feedback to improve quality, the release said.

Students will conduct their research at the Clemson Vehicle Assembly Center, a research assembly line that replicates a real-world car factory. The facility is at Greenville Technical College’s Center for Manufacturing Innovation in Greenville.

David Clayton, the executive director of the Center for Manufacturing Innovation, said the collaboration underscores the depth of cooperation between the institutions on an issue crucial to South Carolina’s economic well-being.

“This program will accelerate what is already one of the fastest-growing manufacturing industries in the country,” he said, in the release. “Greenville Technical College students will have a unique opportunity to advance their education in an environment that closely replicates what happens in an advanced-manufacturing setting, giving them an advantage in the job market. Further, our students, who often have experience in manufacturing, will be well positioned to inform graduate students’ research.”