South Carolina company pioneers renewable natural gas from agribusiness

Jenny Peterson //February 5, 2024//

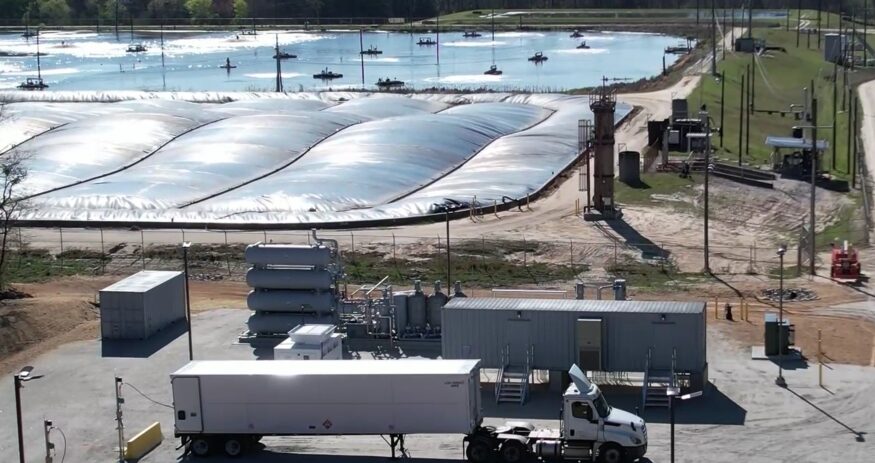

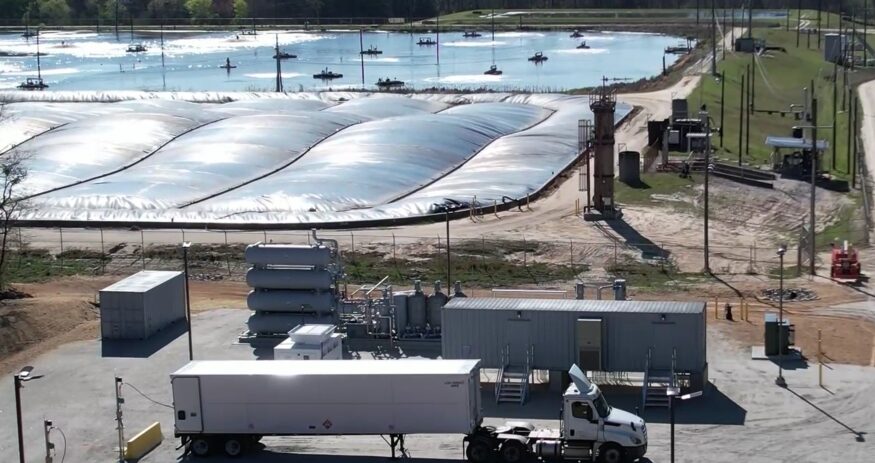

GreenGas USA's project at the Sonoco pulp and paper wastewater treatment facility in Hartsville is one of the company’s large sites. (Photo/GreenGas USA)

GreenGas USA's project at the Sonoco pulp and paper wastewater treatment facility in Hartsville is one of the company’s large sites. (Photo/GreenGas USA)

South Carolina company pioneers renewable natural gas from agribusiness

Jenny Peterson //February 5, 2024//

Where some merely saw a bubbling pond or lagoon — a common catch-all for organic waste and byproducts for large farms and processing facilities — Marc Fetten saw opportunity.

The Charleston resident traveled the world in mergers and acquisitions for a pharmaceutical company. He started his own investment group in 2009 which focused on renewable energy and infrastructure projects and oversaw utility platforms for major industrial parks.

He traveled often to farms and other agribusinesses on business and saw the ponds on site being used to decompose food scraps and organic waste in a process called anaerobic digestion.

He thought, “Why not trap that methane and covert it into renewable natural gas to create a sustainable and climate-friendly way to generate electricity?”

Fetten knew that countries in Europe had already embraced this type of natural gas source rather than rely as heavily on fossil fuels. In South Carolina, however, there wasn’t a big player offering sustainable, renewable natural gas. Fetten saw the opportunity to tap into “Big Ag” agricultural sites.

“These businesses were making methane by letting their organic waste biodegrade on their sites,” Fetten said. “I quickly entered into discussions to see if we could build a renewable business around it, and we had some very willing parties who let us experiment.”

In 2019, Fetten went all in on his latest venture, taking out a mortgage on his home in Charleston to start GreenGas USA as the founder and CEO.

The science involved finding a way to physically cover these ponds, lakes and lagoons — some as large as 20 acres — with a tight synthetic membrane in order to trap the gases coming off of the water and covert the methane into to renewable natural gas, transportable by tank that could be brought directly to a natural gas pipeline.

Using specialized equipment installed on site at these agribusinesses, Fetten found the science was a success. GreenGas USA found a way to prevent harmful methane gas from seeping into the atmosphere, transforming it into renewable natural gas.

Fetten and his team of 11 employees hit the ground to find agribusiness partners willing to have their ponds covered and converted, as well as finding business customers interested in buying the renewable natural gas.

Early agribusiness partners that were testing grounds included McCall Farms in Effingham; Perdue Farms chicken processing facilities in Lewiston, N.C. (now at a second location at their site in Cromwell, Ky.) and Sonoco’s wastewater treatment site in Hartsville. GreenGas USA installed millions of dollars in equipment at each site to capture the methane to turn it into renewable natural gas.

While the renewable natural gas is a higher price point than traditional fossil fuel, Fetten said many large manufacturers and business owners that purchase carbon and renewable gas are interested in the model to help reduce global warming by taking methane, a highly potent greenhouse gas, out of the atmosphere. GreenGas USA is used by customers as a zero and negative carbon fuel source to offset and reduce fossil fuel consumption.

“We’re doing a lot to curb global warming and creating a renewable fuel that replaces fossil fuel,” Fetten said. “By the time we’re done treating it, it’s exactly the same (output) as fossil natural gas and it can be used in the same way.”

An early customer of the renewable natural gas was Mercedez-Benz in Ladson, which signed a long-term contract with GreenGas USA and will use the natural gas to power its paint shop, Fetten said.

“South Carolina has done a really good job of recruiting Western European-owned manufacturers. If I had to rate interest from companies (in battling climate change), it’s companies that are rooted in Western Europe,” Fetten said. “Amazon, which buys a lot of their vans, I imagine has asked them to find ways to make the manufacturing process carbon neutral. That includes converting things like their paint shop from fossil gas to renewable natural gas.”

The “sales” portion of the business continues to be equal parts selling and education, teaching potential customers about the science of removing methane from the environment and the ability to set new industry sustainability standards.

An average day for the executive team could be talking with a chief sustainability officer at a Fortune 500 company — either about selling gas to them or capturing gas from their operations; working on the technical side by monitoring the amount of gas that’s being produced in agribusiness lagoons and tweaking treatments and settings on equipment. The company also does a lot of innovation.

“We came up with a system that isolates the CO₂ out of these lagoons and we’re using it to make cryogenic material,” Fetten said.

The business is also boon to the agribusiness sector, as GreenGas USA ends up paying the farmers and agribusiness partners for their methane-produced natural gas, which is shipped by GreenGas USA employees to major customers across South Caroliana and beyond.

“We end up paying the farmer for their waste — something that is worthless to them and actually quite a nuisance. We invest money to make their system better, make a renewable fuel out of it and once we’ve repaid ourselves for the project, we end up cutting them checks,” Fetten said.

Bringing the business nationwide

What started from humble beginnings is now poised to be a major partner with big agribusiness and large customers and could disrupt a dependence on fossil fuels.

Just more than three full years after launching the business, GreenGas USA is backed by massive investments including IFM Investor, an Australian pension fund with $143 billion under management that invests in renewable businesses, Fetten said. A leading model for industry-led climate solutions, GreenGas USA now has 50 full time employees and is on its third round of fundraising.

“We’ve got five operating sites (on agribusinesses), five under construction and we’ll probably build another 20 over the next year or two,” Fetten said. “We’re growing really quickly. We’ve had 52 offers for capital (fundraising).”

While the majority of customers are carbon and renewable energy buyers in South Carolina, Fetten has expanded the business nationwide. He said plans to make an announcement about a partnership with a major customer in North Carolina within the next few weeks. The company has even installed specific infrastructure to make transporting the natural gas easy and efficient across state lines.

“We’ve built two pipeline injection points in Georgetown, S.C., and in Pleasant Hills, N.C., so if the local pipeline won’t let us inject near where we make the gas, we compress it and truck it to these pipeline injection points and then we can bring it anywhere in the country from there,” Fetten said.

Customers are located in Colorado, Kentucky, Florida and Texas. Fetten said there is growing interest every day in the product and its ability to take greenhouse gases out of the atmosphere.

“We’re learning that coastal communities have a much greater appreciation for climate change because they actually see it. If you talk to people in Miami or Wilmington or Charleston or Savannah, they ‘get it’ and they’re in the process of using taxpayer money to fight flooded roads and drainage systems,” Fetten said.

In order to be a true disrupter for fossil fuels, the company needs to continue to create great partners in Big Ag and beyond. Municipal wastewater treatments facilities may be the next untapped resource to capture methane for renewable natural gas, Fetten said.

“The demand for the gas is more than double the amount that we can make on any given day, so our focus as a management team is to find more and more sources, not just to satisfy demand, but also because every (pond) that we cover and treat is less methane going to the atmosphere. It satisfies our environmental desires of doing good things,” Fetten said.

He said the team is working on being able to create technology to apply the model to smaller farms.

“It’s a matter of scale. The technology doesn’t exist yet to do small farms, but it’s getting there. We started with ‘Big Ag’ but over time, I think we’ll see us being in smaller farms,” Fetten said. “We need to go national to really have the environmental impact that we want. Fortunately, many of the companies we work with do have a national footprint.”

r